Sometime around 1896 Joseph William Wadkin started his Company, along with his sister’s husband, Denzil John Jarvis, who already had his own shop-fitting business, Messrs JD Jarvis & Company, Midland shop fitting works. The two men had an idea for a ‘pattern milling machine’ that would carry out processes that had traditionally been done by hand. Thus Wadkin & Co began in the London Street, Leicester factory with a workforce of just seven men.

By 1904, as well as supplying their pattern milling machine they were making a range of single purpose machines with the main intention of equipping pattern shops, but this of course led to an even wider marketplace.

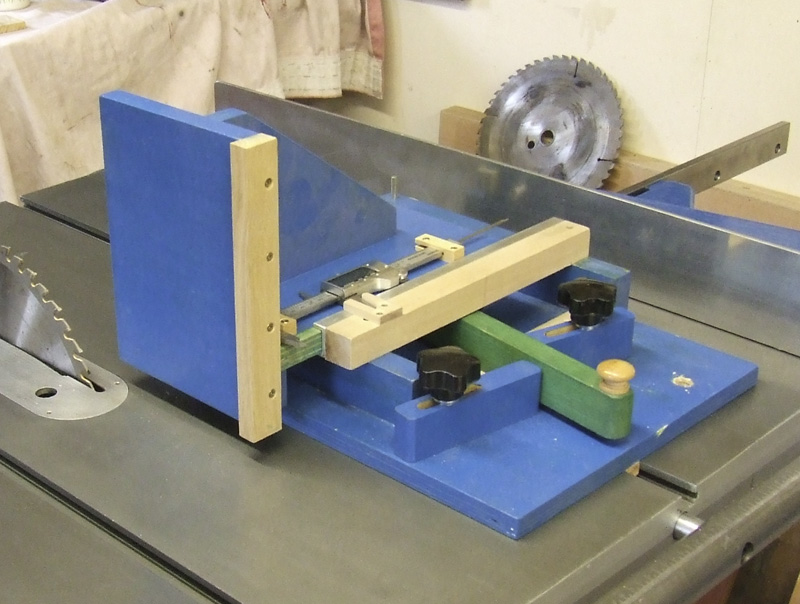

The Wadkin & Co machine was supplied with attachments for numerous and varied operations, and was almost exclusively sold to pattern shops and shipbuilders. So consequently their customers were not predominantly woodworkers, but engineers with a generally regarded greater understanding of machinery. Thus, probably for the first time, woodworking machinery had to be manufactured to exacting standards to satisfy engineers. This was the real beginning of woodworking machinery built to machine-tool standards.

In 1901 they took out a U.K. patent and in 1907 a U.S. patent for a machine which they described as a ‘Mechanical Woodworker’ that could do any operation in ‘Pattern Work also Joinery and cabinet work’ outside of conventional ripping, planing and thicknessing, due to its universal spindle and table movement.

Wadkin was the first U.K woodworking machinery manufacturer to actively promote sales of U.K woodworking machinery in Russia, Europe and the United States. In fact Wadkin & Co. promoted their ‘mechanical woodworker’ over a vast area of Europe and the USA. The Oliver Machinery Company in Grand Rapids, Michigan was given the American franchise in 1908. In the May 1909 issue of the American Journal ‘In the Foundry’ there is an illustrated article describing the machine in great detail. The concludes with “this machine is made by Wadkin & Co., Evington Engineering Works, Leicester, England, and is sold by the Oliver Machinery Company, Grand Rapids, Michigan, U.S.A.”

It proved to be a difficult business relationship though and Joseph Wadkin left the Company and by 1908 the partnership had been dissolved.

Joseph Wadkin went into Partnership with Thomas Scott-King and set up a new Company in Nottingham called Wadkin Mills. (This firm was subsequently sold to the original Wadkin concern following the death of Joseph Wadkin from pneumonia in 1919) they patented together a new machine to ‘produce irregular forms which will stand relative to all other single function wood working machines as the universal milling machine stands to all other metal working machines’.

Mr Jarvis remained with the original Company and being determined to expand the business he enlisted the assistance of a friend, Mr Wallace Goddard who was a manufacturing chemist in Leicester and owned the manufacturing firm ‘Plate Powders’.

Soon after in 1910, Mr Jarvis got to know Mr Ionades an innovative Greek man who had invented an advanced carburettor. They received confirmation that General Motors in the US were interested in their Polyrhoe carburettor design and Denzil Jarvis was invited over for a meeting with Henry Ford to discuss a business deal. Consequently, as his means of travel he booked his passage on the ill-fated Titanic. He set sail on the 10 April 1912 and was travelling on a £13 ticket in second class, and was in a smokers’ lounge at the time the iceberg hit. Responding to a question about the iceberg from a fellow passenger, who survived, he is quoted as saying: ”Well I am accustomed to estimating distance and I put it at between 80 and 90 feet. His body was never recovered.

And so Wallace Goddard was left alone with the business in Leicester, but he was unable to run it single-handed, so he sought the help of his eldest son, Joseph Holland Goddard to run the Company. At this time J.H. Goddard was in the process of becoming an American citizen as he had emigrated to America, but he cancelled his plans and returned to manage the Wadkin Company with his father. Within two years of joining his father in the business the First World War broke out and straightaway J.H. Goddard joined up. He became a commissioned officer and served as a despatch rider in France for the whole length of the War.

During this period the business was managed by the senior employees, and during the 1914-1918 war, the Government commissioned Wadkin & Co to assist in the development of a machine that could produce, at high-speed, large numbers of wooden propellers for the R.A.F.

After the war ended J.H. Goddard returned to run the Company in 1919. After the war there was a tremendous demand for woodworking machinery and the Company’s order books were overflowing and well beyond their limited production capacity. To cope with the immediate demand sub-contractors were used.

Then Goddard and his Son designed and built a new factory at Green Lane Road, Leicester. This factory was well equipped with the latest single-purpose machine tools for high speed batch production.

The development of the integral electric drive in the 1920s led to the introduction of much more efficient brands of woodworking machines. And Wadkin, in particular, pioneered high-speed, high-production machines that produced quality finished woodwork.

A sub-section of the 1922 ‘Who’s Who in Engineering’ showed:

WADKIN & Co., Woodworking Machinery Engineers, North Evington, Leicester.

T.A. Woodworker, Leicester.

Telephone No: 3614 and 3615.

Established 1896.

Employees: 150.

Principals J. W. Goddard, J. H. Goddard.

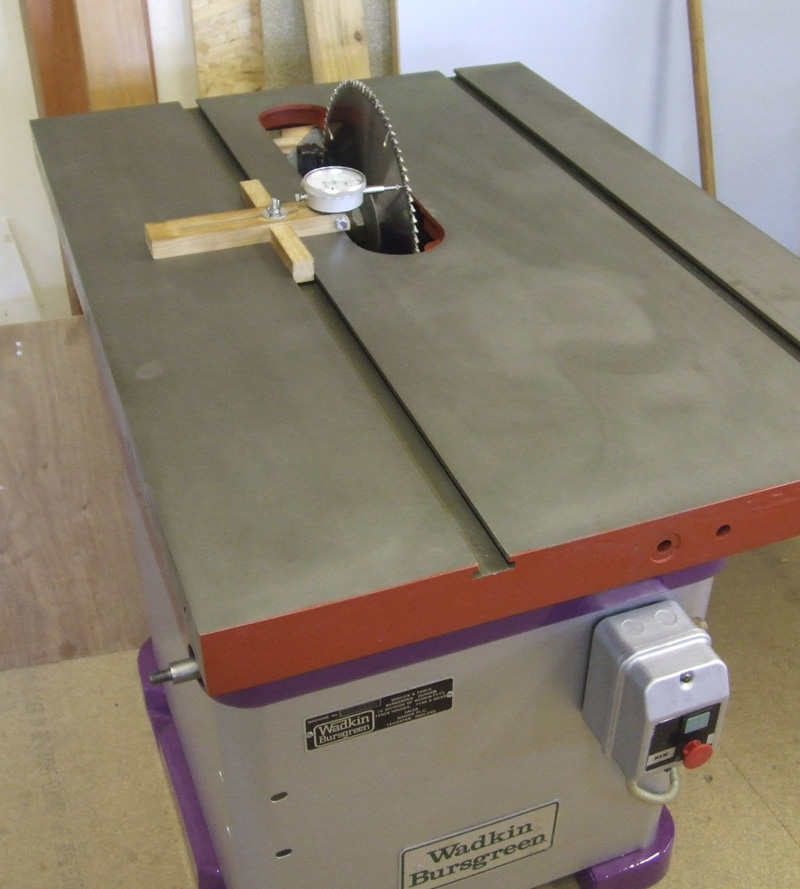

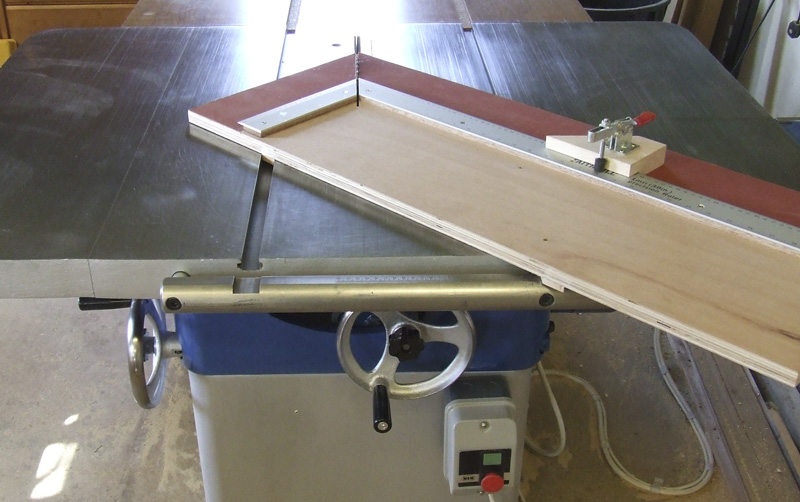

Products: The new mechanical woodworker; saw benches, band-sawing machines, planing machines, spindle moulders, drilling machines, wood-turning lathes and sandpapering machines.

In 1923 J.H. Goddard was to make ‘selling history’ when he set off on a World tour of colossal duration that lasted two and a half years! His aim was to procure agents and build a substantial export business for their U.K machines; principally the Pattern Miller. Their range also included specialist machines, like the ‘wood-propeller shaper’ developed during the War. There was also a range of single-purpose basic woodworking machines.

The tour circled the world but the first country to be visited, in November 1923, was India. Further visits followed to Japan, Java, Australia, New Zealand, Ceylon, Singapore, Hong Kong, Shanghai, Canada and the U.S.A. And he visited Australia and New Zealand on more than one occasion.

His role was to set up agencies and then machines for stock were ordered from the U.K. Later the country would be revisited to make sure that the stock was suitable and satisfactory and that sales were being created. He eventually returned to the UK in January 1927 following the successful sale of many Pattern Millers during his final visit to the U.S.A.

His return was timely as his father passed away in 1927. Throughout this time the Wadkin business letter heading showed the father and son as partners.

Wadkin further extended their range throughout the 1930s and forged ahead in the high technology market and were soon making larger, high production woodworking machines such as double-ender machines, high capacity saws and moulders.

In 1935 they became a Private Company