This is the later model Wadkin Bursgreen 12AGS with the much improved new style fence. The machine has been completely stripped down and meticulously reassembled complete with new dual-voltage motor, arbor bearings and belts.

Size of table 865 x 1220mm - Total Weight roughly 275kg

(click on any image to enlarge)

Image below shows the arbor assembly completely restored to new condition, including two new arbor bearings.

Then the arbor assembly is pressed into the spindle housing, which also incorporates the Riving knife pivot bracket

And the spindle pulley replaced.

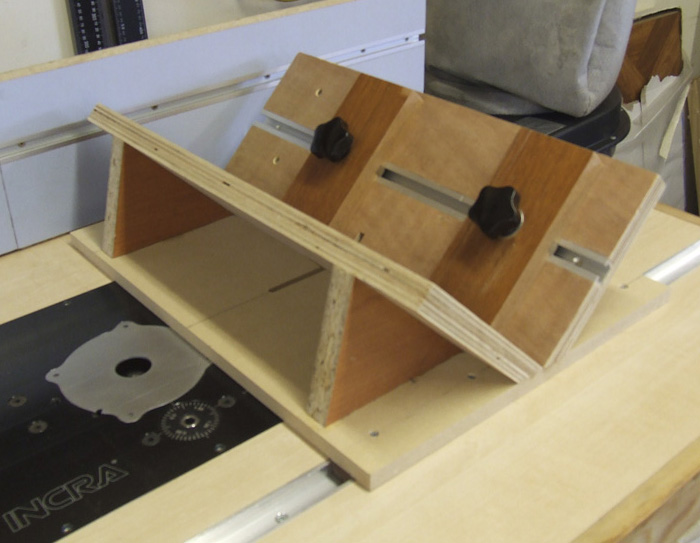

Now all the restoration work is complete I can start reassembling the machine

This image of the interior of the restored cabinet shows the canting shaft and worm

And now the Trunnion bracket is refitted

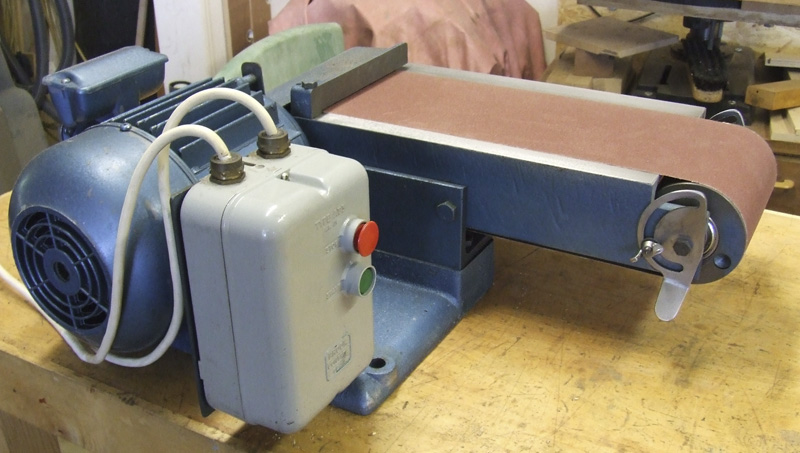

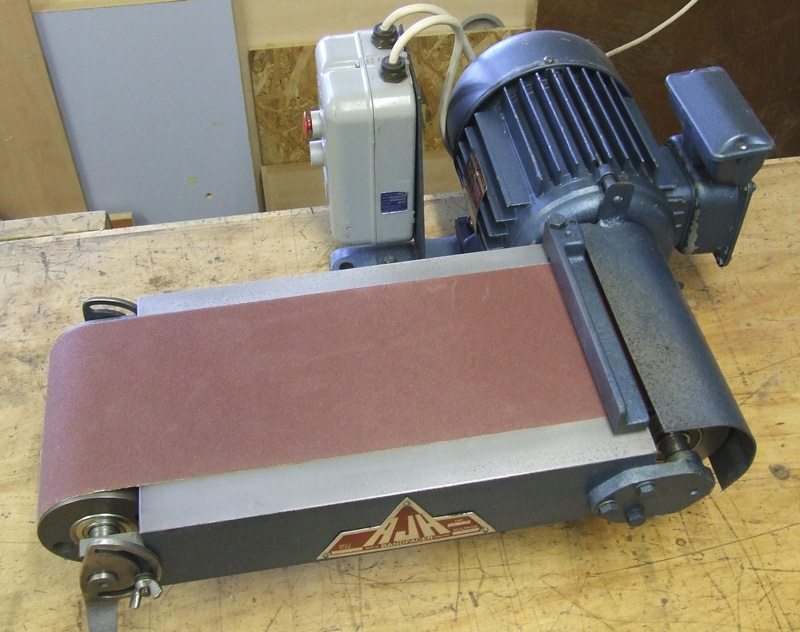

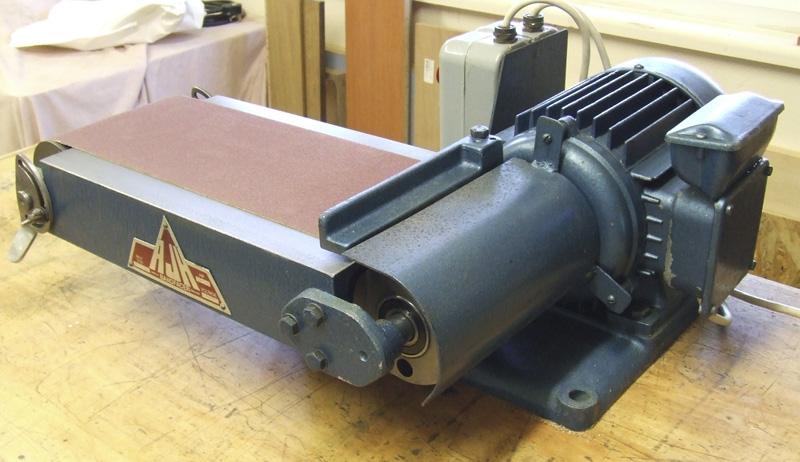

A few more parts installed along with a new 3-phase dual-voltage 3hp electric motor, and a pair of new vee belts.

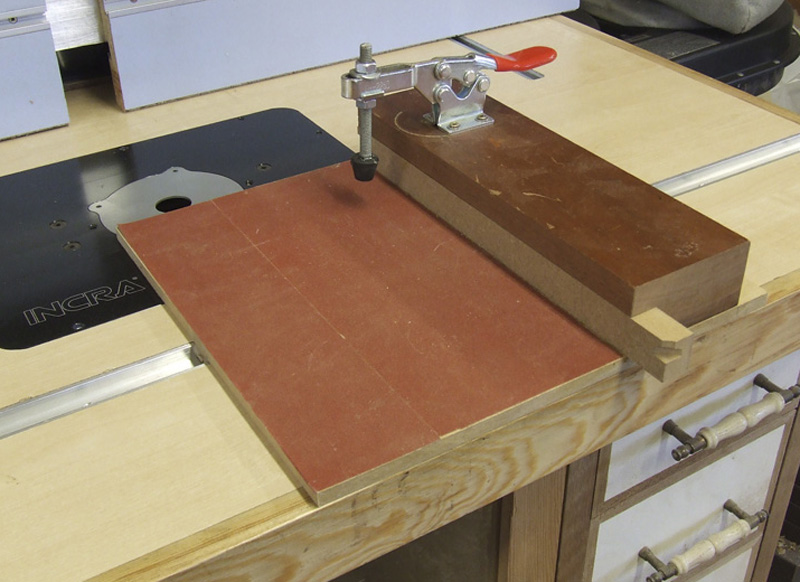

The tables have been cleaned and de-rusted and although they are nice and flat they are stained pretty bad and not finished as well as I would have liked.

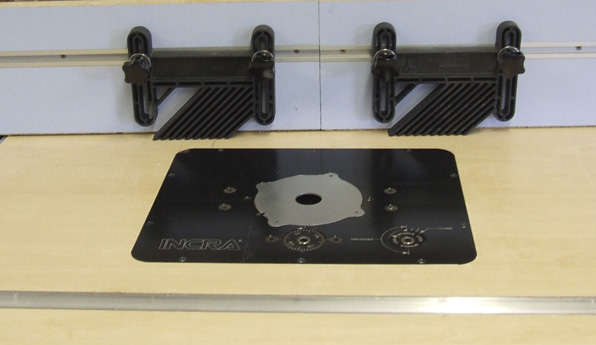

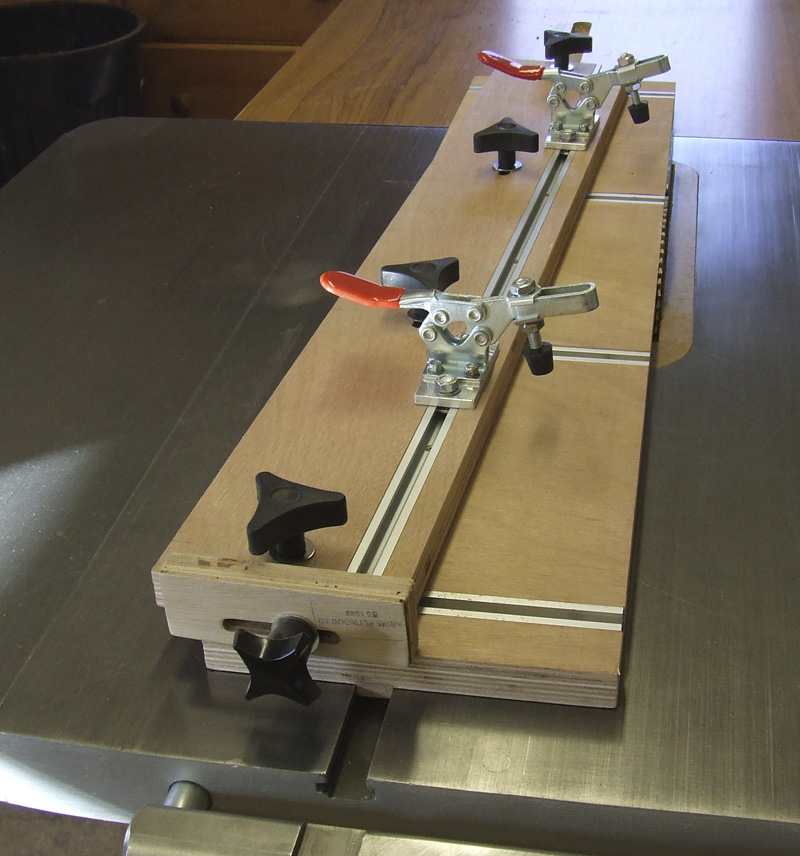

Front rail and fence refitted and the machine is pretty well complete, apart from a few small minor details such as the swivel handles to fit, and once I’ve checked fence alignment then it will be ready to use.

I’m not fitting the on/off switch to the machine but instead I’m fixing it on the adjacent wall as it’s much easier to access.